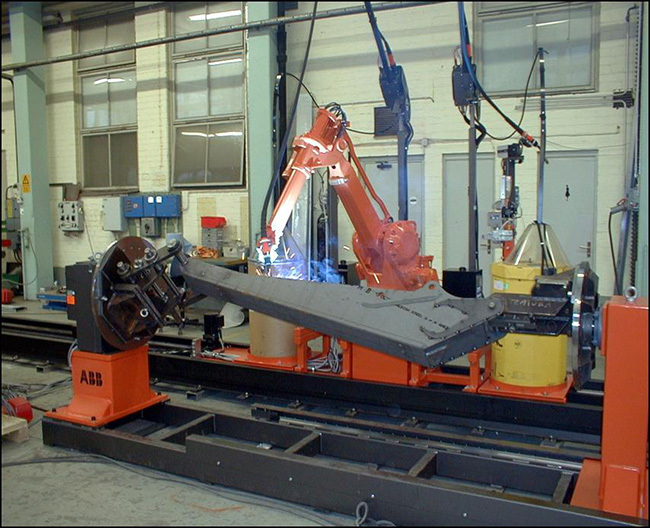

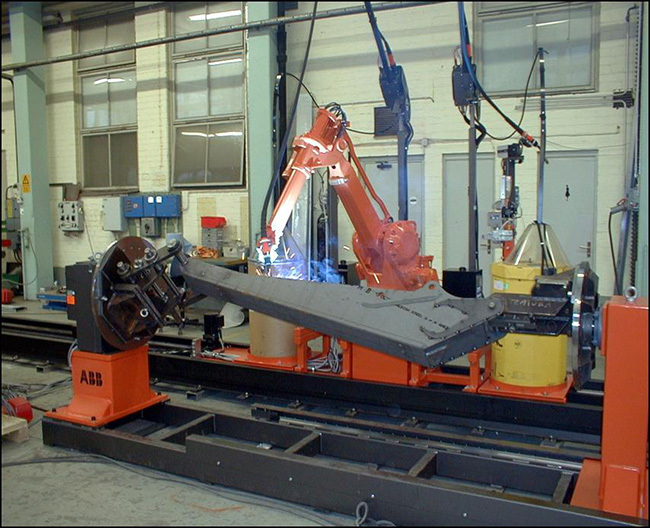

关于焊接夹具中的定位器的介绍!

来源:http://www.tayfsk.com/ 发布时间:2021-10-11 浏览次数:0

定位器在焊接生产中经常使用的定位器有挡铁、定位销、V字铁和样板等。定位销和样板可以独立使用,挡铁和V字铁通常安装在焊接夹具的支承件上使用。安装在夹具上的定位器除起定位作用外,还要和夹紧器配合起来承受各种力,如夹紧力、焊接变形引起的约東力等。

Positioners are often used in welding production, such as retaining iron, locating pin, V-shaped iron and template. The locating pin and template can be used independently. The retaining iron and V-iron are usually installed on the support of the welding fixture. The positioner installed on the fixture not only plays the role of positioning, but also cooperates with the clamp to bear various forces, such as clamping force, yodong force caused by welding deformation, etc.

一、挡铁

1、 Retaining iron

挡铁是应用普遍,结构简单的一种定位器。固定挡铁按定位原理直接把它们焊到钢制的支承件上。可拆挡铁直接插入支承件的锥孔上,不用时可以拔除。为了便于工件的装上和卸下还有一种就是可退出的挡铁。

Retaining iron is a positioner with common application and simple structure. The fixed retaining iron is directly welded to the steel support according to the positioning principle. The detachable retaining iron is directly inserted into the conical hole of the support and can be pulled out when not in use. In order to facilitate the loading and unloading of workpieces, there is also a retractable retaining iron.

二、定位销

2、 Locating pin

它是靠圆柱面与工件的定位基准孔接触进行定位的。在焊接生产中,工件度不大,多用短定位销。位销除固定在夹具上使用的以外,还有设计成可拆的。

It is positioned by the contact between the cylindrical surface and the positioning reference hole of the workpiece. In welding production, short locating pins are often used because the degree of workpiece is not large. In addition to being fixed on the fixture, the positioning pin is also designed to be detachable.

三、Ⅴ字铁

3、 V-shaped iron

直径较小的圆柱工件,如棒和钢管进行对接时,常使用ⅴ字铁定位。ⅴ字铁的槽口的其余尺寸决定于工件的直径D。一般h=0.8D

V-shaped iron is often used to locate cylindrical workpieces with small diameter, such as rod and steel pipe. The remaining dimensions of the notch of V-shaped iron depend on the diameter D of the workpiece. General H = 0.8d

H-h=0.2D,当Φ=90时,C=1.41D-2(H-h)。

H-H = 0.2d, when Φ= At 90, C = 1.41d-2 (H-H).

四、样板

4、 Template

预先按各零件的相互位置制作样板,装配讣使它和工件紧靠进行定位。

Make a template according to the mutual position of each part in advance, and assemble it to make it close to the workpiece for positioning.

上一篇:怎么选择自动焊接机器人的工件附件?

下一篇:使用焊割设备过程中的注意事项!