为什么要用数控切割机?

来源:http://www.tayfsk.com/ 发布时间:2023-06-20 浏览次数:0

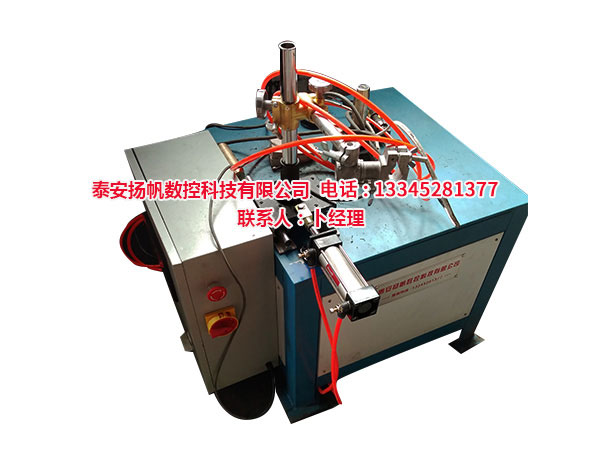

山东数控焊接设备中,数控切割机按照结构方式分类有很多种,重庆金多利科技有限公司出产的数控切割机有便携式、悬臂式、台式、式、相贯线式等多种。下面咱们就来着重谈谈数控切割机。数控切割机,因其外形像门而得名,是一种高能效钢板自动切割下料设备。

In Shandong CNC welding equipment, there are many types of CNC cutting machines classified according to their structure. The CNC cutting machines produced by Chongqing Jinduoli Technology Co., Ltd. include portable, cantilever, desktop, and intersecting line types. Now let's focus on CNC cutting machines. CNC cutting machine, named after its appearance resembling a door, is a high-efficiency automatic cutting and cutting equipment for steel plates.

数控切割机有数控系统、驱动系统、控制系统、机械传动系统、等离子切割系统、火焰切割系统、套料软件组成,主要用于金属板材平面各种形状的等离子切割、火焰切割和直线火焰切割,人机界面友好,操作简单,自动化程度高,切割精度高,切割速度快,工件变形小,切割质量好,动态稳定性好。

CNC cutting machines are composed of CNC systems, drive systems, control systems, mechanical transmission systems, plasma cutting systems, flame cutting systems, and nesting software. They are mainly used for plasma cutting, flame cutting, and linear flame cutting of various shapes of metal sheet planes. The human-machine interface is friendly, the operation is simple, the degree of automation is high, the cutting accuracy is high, the cutting speed is fast, the workpiece deformation is small, the cutting quality is good, and the dynamic stability is good.

数控系统、伺服系统、电器系统、等离子系统、火焰切割系统均采用主流,性能好,可靠性高。对于那些采用传统方式难以切割的材料,不锈钢、铜、铝及铝合金等有色金属可通过数控等离子切割机完成,在切割速度上,数控等离子切割速度快于传统火焰切割速度的2到3倍,切割面光洁,热变形小。

The CNC system, servo system, electrical system, plasma system, and flame cutting system all adopt mainstream brands, with good performance and high reliability. For materials that are difficult to cut using traditional methods, non-ferrous metals such as stainless steel, copper, aluminum, and aluminum alloys can be cut using CNC plasma cutting machines. In terms of cutting speed, CNC plasma cutting speed is 2 to 3 times faster than traditional flame cutting speed, with smooth cutting surfaces and small thermal deformation.

加上13把直条火焰切割枪可用于钢板快速分条,广泛应用于钢结构加工、机械制造、造船业、起重运输、建筑钢模、重型机械、压力容器、化工机械、锅炉制造、机车制造、石化设备、矿山机械等。

In addition, 13 straight flame cutting guns can be used for rapid slicing of steel plates, widely used in steel structure processing, mechanical manufacturing, shipbuilding, lifting and transportation, construction steel molds, heavy machinery, pressure vessels, chemical machinery, boiler manufacturing, locomotive manufacturing, petrochemical equipment, mining machinery, etc.

很多机械加工类企业都会选择用数控切割机设备来进行切割下料。数控切割机与其他切割机的区别在于,可根据需要增加多支割炬,可达到“一机两用”的效果,不仅如此,式切割机切割幅面更广,可应对大型板材的切割工作。

Many mechanical processing enterprises choose to use CNC cutting machine equipment for cutting and cutting. The difference between CNC cutting machines and other cutting machines is that multiple cutting torches can be added as needed to achieve the effect of "one machine for two purposes". Moreover, the CNC cutting machine has a wider cutting range and can handle large sheet metal cutting work.

相比激光切割机,数控切割机作为一种低成本的机型,数控切割机即使在激光切割机成为主流产品的环境下,仍有一定的市场需求。就切割加工的应用环节而言,切割机满足了企业对钢板切削加工的机动性要求,满足了对错综复杂的图形零件下料要求。型材切割机虽然成本低,但是只能切割直线和直径不大的圆,而且切割精度低;大型激光切割机虽然功能强大,但是太高。

Compared to laser cutting machines, CNC cutting machines, as a low-cost model, still have a certain market demand even in the environment where laser cutting machines have become mainstream products. In terms of the application process of cutting processing, the cutting machine meets the mobility requirements of enterprises for steel plate cutting processing and the cutting requirements for complex graphic parts. Although the profile cutting machine has low cost, it can only cut straight lines and circles with small diameters, and the cutting accuracy is low; Although large laser cutting machines have powerful functions, their prices are too high.

数控切割机与激光切割机一样,可切割由直线和圆弧组成的任意平面形状的零件,加入火焰割炬,更可以切割中、高厚度碳钢板,具有移动方便,操作简单,机动灵活的特点,一次性投入相对较低。因此,在板材下料过程中的应用越来越广泛。您有需求就来咨询我们http://www.tayfsk.com吧!

CNC cutting machines, like laser cutting machines, can cut any planar shape of parts composed of straight lines and arcs. By adding a flame cutting torch, they can also cut medium and high thickness carbon steel plates. They have the characteristics of easy movement, simple operation, and flexibility, with relatively low one-time investment. Therefore, the application in the process of sheet metal cutting is becoming increasingly widespread. If you have any needs, please come and consult us http://www.tayfsk.com Come on!

上一篇:从多个方面探讨自动焊接设备的优势

下一篇:了解到自动焊接专机的注意事项