自动焊接机开关电源、气源、液压源的日常检查

来源:http://www.tayfsk.com/ 发布时间:2023-05-25 浏览次数:0

开关电源、气源、液压源的问题往往会导致山东自动焊接设备出现异常,比如电源系统的问题,涉及到生产车间所有的电源系统故障,比如电源低、烧坏、电源线插头松动、接触不良等。

The problems with switching power, air, and hydraulic sources often lead to abnormalities in Shandong automatic welding equipment, such as power system problems, which involve all power system failures in the production workshop, such as low power supply, safety burning, loose power cord plugs, and poor contact.

气泵或液压泵未打开时,气动三联或双接头未打开,液压传动系统中的卸荷阀或某些压力阀未打开等。,测试仪器时要涉及到以下几个方面:开关电源,涉及到各机器设备供电系统的开关电源和生产车间的电源。

When the air pump or hydraulic pump is not turned on, the pneumatic triple or double joint is not turned on, and the unloading valve or some pressure valves in the hydraulic transmission system are not turned on., When testing instruments, the following aspects need to be involved: switching power supply, which involves the switching power supply of various machine equipment power supply systems and the power supply of production workshops.

自动焊接机压力调节阀、继电器、流量调节阀的常规检查

Routine inspection of pressure regulating valves, relays, and flow regulating valves for automatic welding machines

继电器和磁感应感应器一样,长期使用会导致接地的粘结,无法保证用电设备的正常控制电路。焊接机和设备需要更换。在气动或液压传动系统中,节流阀的开度和压力阀的压力调节变黄,机器和设备的振动会导致松动或滑动。这些装置和传感器一样,都是自动化机械中日常工作中需要维护的部件。

Relays, like magnetic induction inductors, can lead to ground bonding after long-term use, which cannot guarantee the normal control circuit of electrical equipment. The welding machine and equipment need to be replaced. In pneumatic or hydraulic transmission systems, the opening of the throttle valve and the pressure regulation of the pressure valve turn yellow, and the vibration of machines and equipment can cause loosening or sliding. These devices, like sensors, are components that require maintenance in daily work of automated machinery.

例行检查自动焊接机的传感器位置是否偏移

Routine check if the sensor position of the automatic welding machine is offset

由于设备维护和管理人员的疏忽,很可能会遗漏一些传感器的位置,如不到位、传感器故障、灵敏度故障等。,所以需要例行检查传感器的传感技术位置和灵敏度,如有偏差立即调整。如果传感器损坏,请立即更换。很多时候,除此之外,因为自动化机械的震动,大部分传感器在长期使用后都会松动。因此,在日常工作和维护中,需要定期检查传感器的位置是否合理,固定是否牢固。

Due to the negligence of equipment maintenance and management personnel, it is possible to miss the location of some sensors, such as inadequate positioning, sensor failure, sensitivity failure, etc., So it is necessary to regularly check the sensor's sensing technology position and sensitivity, and adjust immediately if there is any deviation. If the sensor is damaged, please replace it immediately. Many times, in addition to this, due to the vibration of automated machinery, most sensors become loose after long-term use. Therefore, in daily work and maintenance, it is necessary to regularly check whether the position of the sensor is reasonable and whether it is firmly fixed.

例行检查自动焊接机的电磁阀是否有换向操作

Routine inspection of the electromagnetic valve of the automatic welding machine for reverse operation

电磁阀通过电磁铁吸引阀芯,使气缸做好换向工作。当电磁铁不工作时,阀芯不工作,导致气缸不能工作。如果气控回路中湿气和烟雾太多,阀芯就会被卡住、堵塞,然后气缸就不能工作了。

The solenoid valve attracts the valve core through an electromagnet, enabling the cylinder to perform reversing work. When the electromagnet is not working, the valve core does not work, resulting in the cylinder not working. If there is too much moisture and smoke in the air control circuit, the valve core will be stuck, blocked, and the cylinder will not work.

自动焊接机所有控制电路的常规检查

Routine inspection of all control circuits of automatic welding machines

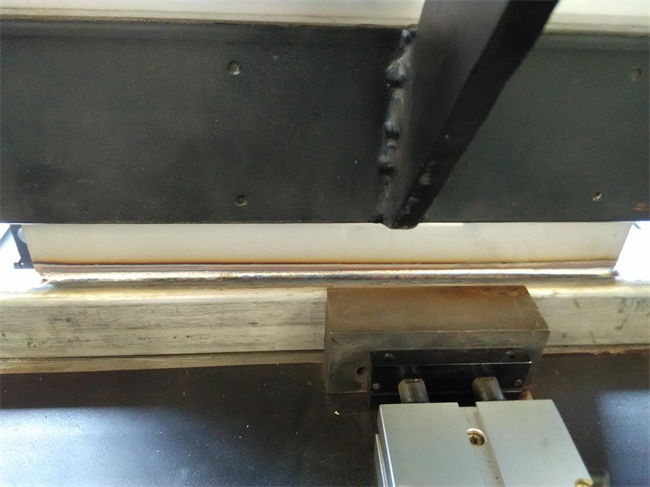

检查电路中的电线是否短路,特别是线槽中的电线是否因拉扯而被线槽切断,检查气管是否有损坏的折痕,检查液压油管是否堵塞。如果气管严重折皱,应立即更换,液压油管也应更换。

Check if the wires in the circuit are short circuited, especially if the wires in the trunking are cut by the trunking due to pulling, check if there are any damaged creases in the air pipe, and check if the hydraulic oil pipe is blocked. If the trachea is severely wrinkled, it should be replaced immediately, and the hydraulic oil pipe should also be replaced.

在自动焊接机确保申诉方法步骤正确后,故障很可能出现在自动机的控制面板,但不可能是程序问题。,控制面板损坏是毫无疑问的。只要没有严重的短路故障,控制面板内部是有短路保护的,通常的短路故障是不会烧坏控制面板的。更多相关事项就来我们网站http://www.tayfsk.com咨询!

After the automatic welding machine ensures that the appeal method steps are correct, the fault is likely to occur in the control panel of the automatic machine, but it cannot be a program issue. Firstly, there is no doubt that the control panel is damaged. As long as there is no serious short circuit fault, the control panel has short circuit protection inside, and normal short circuit faults will not burn the control panel. For more related matters, come to our website http://www.tayfsk.com consulting service

上一篇:环缝焊接专机的原理以及功能特点

下一篇:如何在焊接机器人进行设备预测性维护?