焊接因素会影响焊接机器人的焊接

来源:http://www.tayfsk.com/ 发布时间:2022-01-13 浏览次数:0

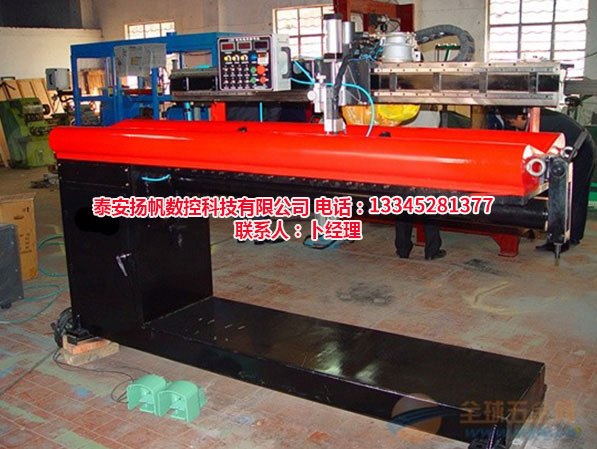

焊接机器人不仅使焊接操作变得越来越容易,而且很大程度上保障了操作人员的工作环境。提高劳动生产率;提高工人的工作强度,能在有害环境下工作;并减少工人的处理。技术要求。应该知道,机器人焊接变位机、工具附件和焊丝都会对焊接机器人的焊接工作产生一定的影响。

Welding robot not only makes welding operation easier and easier, but also ensures the working environment of operators to a great extent. Improve labor productivity; Improve the working intensity of workers and be able to work in harmful environment; And reduce the handling of workers. Technical requirements. It should be known that robot welding positioner, tool accessories and welding wire will have a certain impact on the welding work of welding robot.

一、变位机和机器人焊接装置对焊接的影响

1、 Influence of positioner and robot welding device on welding

1、对零件定位精度要求较高,焊缝相对位置精度较高,应≤1mm。

1. The positioning accuracy of parts shall be high, and the relative position accuracy of welds shall be ≤ 1mm.

2、它们的定位和保持是单独完成的。

2. Their positioning and maintenance are completed separately.

3、机器人焊接装置前后工序的定位一定要一致。

3. The positioning of the robot welding device before and after the process must be consistent.

4、由于变位机行程角度较大,机器人焊接装置应尽量避免使用可移动的手动螺栓。

4. Due to the large stroke angle of the positioner, the robot welding device should try to avoid the use of movable manual bolts.

5、机器人焊接工具附件应尽量采用快速压紧件,并配有带孔的平台。牢牢握住压缩夹。

5. The accessories of robot welding tools shall adopt quick compression parts as far as possible, and shall be equipped with platforms with holes. Hold the compression clip firmly.

6、不同于普通焊接治具,机器人焊接治具不仅可以正面焊接,还可以侧面焊接工件,可以无限延伸。

6. Different from ordinary welding fixture, robot welding fixture can not only weld the front, but also weld the workpiece on the side, which can extend infinitely.

二、焊丝对焊接机器人焊接过程的影响。

2、 Influence of welding wire on welding process of welding robot.

为了减少更换焊丝的频率,机器人需要使用加农焊丝。但由于是加农焊丝,送丝软管很长,强度高,对焊丝的刚性要求很高。

In order to reduce the frequency of welding wire replacement, the robot needs to use cannon welding wire. However, as it is a cannon welding wire, the wire feeding hose is very long and has high strength, which requires high rigidity of the welding wire.

需要注意的是,焊接机器人的日常维护也很重要。只有对焊接机器人进行定期检查和定点维护,才能增加部件的使用寿命,从而延长整机设备的使用寿命。

It should be noted that the daily maintenance of welding robot is also very important. Only regular inspection and fixed-point maintenance of the welding robot can increase the service life of components and prolong the service life of the whole machine.

本文的精彩内容由山东自动焊接设备为您提供,本网站还有很多的精彩内容,更多的内容您可以点击进入:http://www.tayfsk.com我们有专门的客服为您解答问题

The wonderful contents of this article are provided by Shandong automatic welding equipment. There are many wonderful contents on this website. You can click to enter more contents: http://www.tayfsk.com We have special customer service to answer your questions

上一篇:管法兰卧式焊接机的适用范围

下一篇:等离子环缝自动焊机工艺