焊接机器人有自己的智能控制系统

来源:http://www.tayfsk.com/ 发布时间:2023-01-10 浏览次数:0

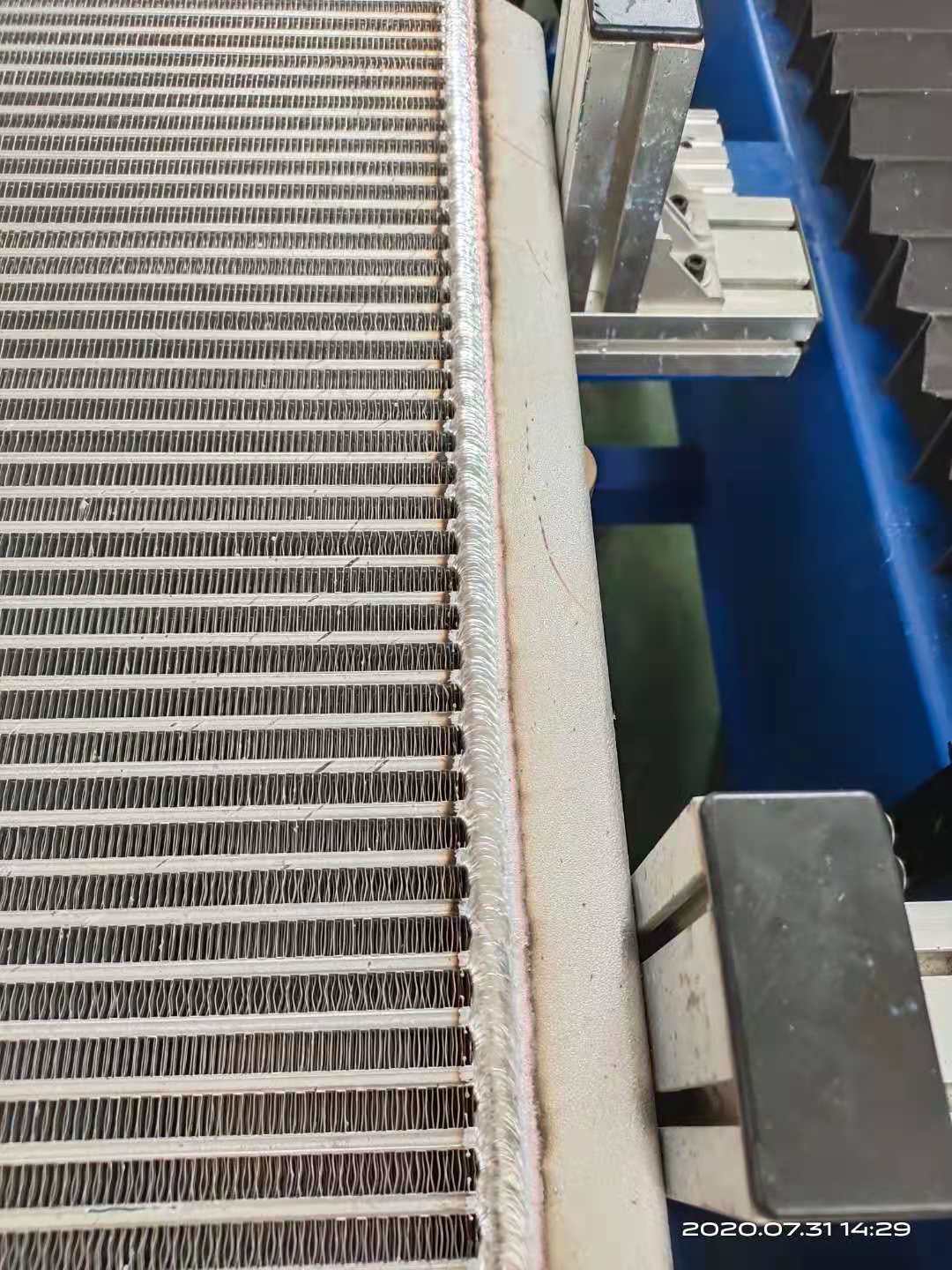

焊接机器人在焊接的过程中,是全自动完成的,并不需要人为去参与,对于焊接的工件能够完成自动化焊接,替代传统的焊接流程,而且焊接的过程中能够确保稳定焊接,提升焊接效率,焊接机器人与传统焊接显著的区别就在于,焊接机器人有自己的智能控制系统。山东自动焊接设备厂家为您讲解其中的信息。

In the process of welding, the welding robot is fully automatic and does not need human participation. For the workpiece to be welded, it can complete automatic welding instead of the traditional welding process. In addition, it can ensure stable welding and improve the welding efficiency. The significant difference between the welding robot and the traditional welding is that the welding robot has its own intelligent control system. Shandong automatic welding equipment manufacturer explains the information for you.

焊接机器人的组成

Composition of welding robot

焊接机器人可以实现自动焊接,归功于它的控制系统、传感器、示教器和执行器。

The welding robot can realize automatic welding thanks to its control system, sensors, teaching devices and actuators.

焊接机器人的控制系统

Control system of welding robot

焊接机器人的控制系统可以实现自动焊接,智能控制系统就和人的大脑一样,可以下达指令来完成一系列的操作,控制系统可以对焊缝智能识别,根据焊缝的规格做出反应,选择合适的焊接参数相匹配,保证焊接的稳定性。

The control system of the welding robot can realize automatic welding. The intelligent control system, like the human brain, can issue instructions to complete a series of operations. The control system can intelligently identify the weld, react according to the weld specification, select appropriate welding parameters to match, and ensure the stability of welding.

焊接机器人传感器

Welding robot sensor

传感器对于焊接机器人的作用日益重要,其中激光传感器和力传感器可以实现焊缝跟踪和自动寻位,提高焊接的精度,还可以帮助工人在远距离实时检测焊接质量,大大提高了焊接机器人的焊接性能和对工作环境的适应性。

Sensors play an increasingly important role in welding robots. Laser sensors and force sensors can realize seam tracking and automatic position finding, improve the accuracy of welding, and also help workers detect the welding quality in real time at a distance, greatly improving the welding performance of welding robots and their adaptability to the working environment.

焊接机器人示教器

Welding robot teaching device

焊接机器人的示教器可以在焊接过程中进行调试焊接和急停作业,焊接过程中如果焊接质量出现问题,工作人员可以手持示教器按下急停按钮,在工作过程中的指令也可以通过示教器来执行。

The teaching device of the welding robot can debug welding and emergency stop operation during the welding process. If there is a problem with the welding quality during the welding process, the staff can hold the teaching device and press the emergency stop button, and the instructions in the working process can also be executed through the teaching device.

焊接机器人执行器

Welding robot actuator

焊接机器人的执行器能够根据设定好的指令来完成一系列焊接作业流程,各个关节还可以协助运动,互相配合来完成焊接作业,不但能够确保焊接质量,焊接效率也大大提高了,降低了企业的人员成本和管理成本。

The actuator of the welding robot can complete a series of welding operation processes according to the set instructions. Each joint can also assist in movement and cooperate with each other to complete the welding operation, which can not only ensure the welding quality, but also greatly improve the welding efficiency, and reduce the personnel cost and management cost of the enterprise.

工业制造离不开焊接,焊接需要工人有熟练的技巧,但是恶劣的焊接环境让工人作业起来变得很困难,这时候焊接机器人应运而生,焊接机器人可以替代90%重复性的简单焊接工作,并且焊接效率高,焊接质量好,这几年在不少领域都有着焊接机器人的身影,你有使用需求就来我们网站http://www.tayfsk.com咨询吧!

Industrial manufacturing cannot be separated from welding. Welding requires skilled skills of workers, but the harsh welding environment makes it difficult for workers to work. At this time, welding robots came into being. Welding robots can replace 90% of the repetitive simple welding work, with high welding efficiency and good welding quality. In recent years, there are welding robots in many fields. If you need to use them, please come to our website http://www.tayfsk.com Ask!