常见自动焊接技术设备管理问题

来源:http://www.tayfsk.com/ 发布时间:2021-12-14 浏览次数:0

常见问题及原因分析: 问题现象、原因分析、解决方法、弱焊(咬痕)焊接温度过低,调整到合适的焊接温度,焊剂不粘或不足,加足焊剂,焊杆耳不干净,焊杆耳清洁,模具温度不足,预热时间延长,气压调整,母线排不平滑,气孔,引线,焊剂过量,焊剂吸干,极耳过长,极耳切割,极耳部分有气孔,极耳熔过,温度过高,调整到适当的焊接温度,下模预热时间过长,铸焊时间过长,铸焊时间过长,调整铸焊时间、母线或部件、不成形、冷却水量不足、水量充足、冷却水泵故障、更换或修理冷却水泵、冷却方式不当、调整冷却方式、拉杆变形等,或拉脱杆组(难脱模)冷却参数不合适,调整冷却方式和方式,气压不够,增加或调整到适当压力,脱模不良,喷淋脱模剂,杆耳焊接不到位,调整杆耳或更换坏杆板,锡含量不足,加锡(锡含量为1-1.5克索)模具预热时间过长,缩短预热时间,使用过程中,按启动按钮不运行,如果实际温度低于温度,调整温度或等待温度上升。

Common problems and cause analysis: problem phenomenon, cause analysis, solution, weak welding (bite mark) the welding temperature is too low, adjust to the appropriate welding temperature, the flux is not sticky or insufficient, add enough flux, the welding rod ear is not clean, the welding rod ear is clean, the mold temperature is insufficient, the preheating time is prolonged, the air pressure is adjusted, the bus bar is not smooth, the air hole, lead wire and flux are excessive, and the flux is sucked dry, The pole lug is too long, the pole lug is cut, there are pores in the pole lug part, the pole lug has been melted, the temperature is too high, adjust to the appropriate welding temperature, the preheating time of the lower mold is too long, the casting welding time is too long, the casting welding time is too long, the casting welding time is too long, the bus or components are not formed, the cooling water quantity is insufficient, the water quantity is sufficient, the cooling water pump fails, the cooling water pump is replaced or repaired, and the cooling method is improper Adjust the cooling mode, pull rod deformation, etc., or the cooling parameters of pull-off rod group (difficult to demould) are inappropriate, adjust the cooling mode and mode, the air pressure is not enough, increase or adjust to the appropriate pressure, poor demoulding, spray release agent, rod lug welding is not in place, adjust rod lug or replace bad rod plate, tin content is insufficient, the preheating time of tin (tin content is 1-1.5 g) mold is too long, shorten the preheating time, During use, press the start button to stop operation. If the actual temperature is lower than the minimum temperature, adjust the minimum temperature or wait for the temperature to rise.

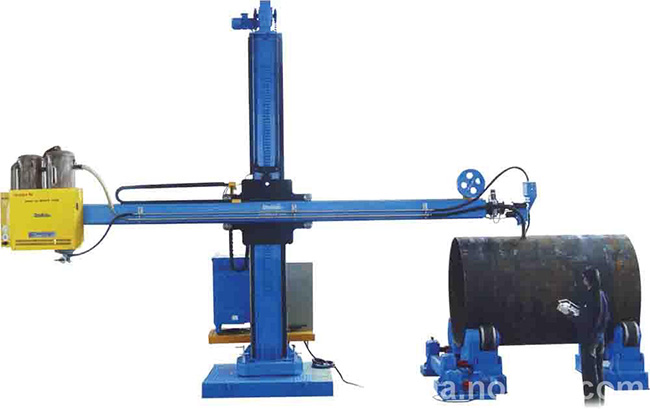

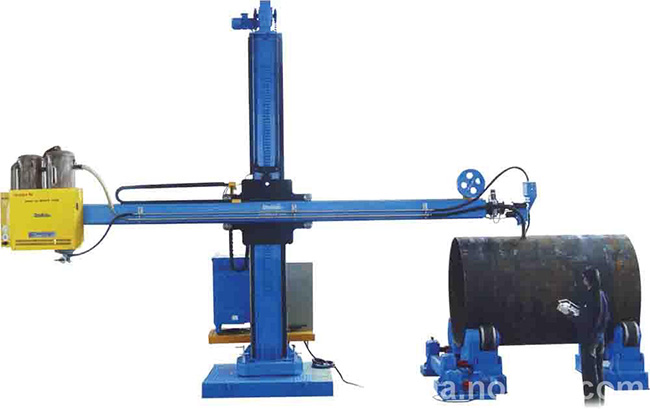

变位机专用焊接辅助设备,适用于回转工作的焊接变位,以得到理想的加工位置和焊接速度。焊接操作机一般由立柱、横梁、回转机构、台车等部件组成。 将焊接机头或焊枪送到并保持在待焊位置,或以选定的焊接速度沿规定的轨迹移动焊剂的装置。数控切割机用数字程序驱动机床运动,随着机床运动时,随机配带的切割工具对物体进行切割。

Special welding auxiliary equipment for positioner is suitable for welding positioner of rotary work to obtain ideal machining position and welding speed. The welding operator is generally composed of columns, beams, slewing mechanisms, trolleys and other components. A device that sends and maintains the welding head or welding gun at the position to be welded, or moves the flux along the specified track at the selected welding speed. CNC cutting machine uses digital program to drive the movement of the machine tool. When the machine tool moves, the random cutting tool is equipped to cut the object.

按开始按钮0.5秒以下,按开始按钮0.5秒以上,按紧急停止按钮旋出重置设备或排除异物,然后重置行程传感器,移动行程传感器,将行程传感器调回原位置,行程传感器损坏,更换传感器,按任意键不要运行,空气源没有打开或空气压力不够,打开或调整空气压力,实际温度低于温度,调整温度或等待温度上升,电脑板冻结,关闭电源重新启动,温度不上升,电热管损坏,更换电热管,水箱水位高于模具进水口或电磁进水阀损坏。

Press the start button for less than 0.5 seconds, press the start button for more than 0.5 seconds, press the emergency stop button to turn out the reset equipment or eliminate foreign matters, then reset the travel sensor, move the travel sensor, return the travel sensor to the original position, the travel sensor is damaged, replace the sensor, press any key not to run, the air source is not opened or the air pressure is not enough, open or adjust the air pressure, If the actual temperature is lower than the minimum temperature, adjust the minimum temperature or wait for the temperature to rise, the computer board freezes, turn off the power and restart, the temperature does not rise, the electric heating pipe is damaged, replace the electric heating pipe, the water level of the water tank is higher than the mold water inlet or the solenoid water inlet valve is damaged.

以上的精彩内容来自:泰安扬帆数控科技有限公司山东自动焊接设备介绍及分享,更多内容请继续关注我们:http://www.tayfsk.com

The above wonderful content comes from the introduction and sharing of Shandong automatic welding equipment of Taian Yangfan CNC Technology Co., Ltd. please continue to pay attention to us for more content: http://www.tayfsk.com

上一篇:山东数控焊接设备的3个装置

下一篇:自动焊机的常见故障都有哪些?