自动焊接设备整机是根据什么原则设计的

来源:http://www.tayfsk.com/ 发布时间:2023-07-06 浏览次数:0

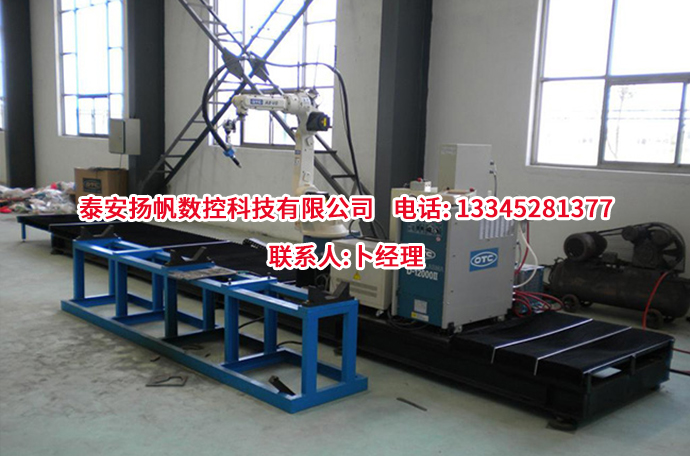

自动焊接设备整机进行设计的时候,具体要如何来设计的,作为山东自动焊接设备厂家,让小编带大家共同了解一下自动焊接设备整机是如何设计的!

When designing the entire automatic welding equipment, how to design it specifically? As a Shandong automatic welding equipment manufacturer, let me take everyone to understand how the entire automatic welding equipment is designed!

1、尺度规划优化原则。当设计要求满足一定工作空间要求时,通过尺度优化以选定臂杆尺寸,这将有利于设备刚度的提高,使运动惯量进一步降低。

1. Principle of scale planning optimization. When the design requirements meet certain workspace requirements, selecting the arm size through scale optimization will be beneficial for improving the equipment stiffness and further reducing the motion inertia.

2、运动惯量原则。由于设备运动部件多,运动状态经常改变,必然产生冲击和振动,采用此原则,可增加设备运动平稳性,提高操作机动力学特性。为此,在设计时应注意在满足强度和刚度的前提下,尽量减小运动部件的质量,并注意运动部件对转轴的质心配置。

2. The principle of motion inertia. Due to the large number of moving components in the equipment, the motion state often changes, inevitably resulting in impacts and vibrations. Adopting this principle can increase the smoothness of equipment movement and improve the dynamic characteristics of operation. Therefore, in design, attention should be paid to minimizing the mass of moving parts while meeting the requirements of strength and stiffness, and to paying attention to the configuration of the center of mass of the moving parts on the rotating shaft.

3、强度高的材料选用原则。由于设备从手腕、小臂、大臂到机座是依次作为负载起作用的,选用强度高的材料以减轻零部件的质量是十分有必要的。

3. Principles for selecting materials with high strength. Due to the fact that the equipment functions as a load sequentially from the wrist, forearm, boom to the base, it is necessary to choose high-strength materials to reduce the quality of components.

4、刚度设计的原则。设备设计中,刚度是比强度更重要的问题,要使刚度更大,一定要恰当地选择杆件剖面形状和尺寸,提高支承刚度和接触刚度,合理地安排作用在臂杆上的力和力矩,尽量减少杆件的弯曲变形。

4. Principles of stiffness design. In equipment design, stiffness is a more important issue than strength. To achieve greater stiffness, it is necessary to appropriately select the cross-sectional shape and size of the rod, improve the support stiffness and contact stiffness, reasonably arrange the forces and moments acting on the arm, and minimize the bending deformation of the rod.

5、工艺性原则。设备采用高精度、高集成度的自动机械系统,良好的加工和装配工艺性是设计时要体现的重要原则之一。仅有合理的结构设计而无良好的工艺性,会导致操作机性能的降低和成本的提高。

5. Principle of craftsmanship. The equipment adopts high-precision and highly integrated automatic mechanical systems, and good processing and assembly craftsmanship is one of the important principles to be reflected in design. Only a reasonable structural design without good craftsmanship can lead to a decrease in the performance of the operating machine and an increase in cost.

此外一般来说,元器件的可靠性应高于部件的可靠性,而部件的可靠性应高于整机的可靠性。可以通过概率设计方法设计出可靠度满足要求的零件或结构,也可以通过系统可靠性综合方法评定设备系统的可靠性。更多相关事项就来我们网站http://www.tayfsk.com咨询!

In addition, generally speaking, the reliability of components should be higher than that of components, and the reliability of components should be higher than that of the entire machine. Parts or structures that meet reliability requirements can be designed using probability design methods, and the reliability of equipment systems can also be evaluated through system reliability synthesis methods. For more related matters, come to our website http://www.tayfsk.com consulting service

上一篇:操作数控焊接设备时的注意事项

下一篇:焊接专机的常用直观法检查方法