数控焊接设备气路常见故障如何处理?

来源:http://www.tayfsk.com/ 发布时间:2023-02-09 浏览次数:0

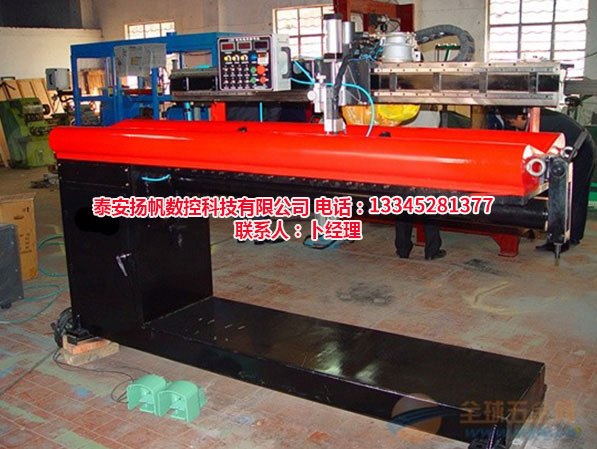

由于数控焊接设备需要以燃气作为切割原料,在日常的使用过程中,相关管气路尤其需要引起操作者的注意,这里山东数控焊接设备厂家为您列举了一些常见的管气路故障及处理办法,希望大家能有所借鉴。

Because the CNC welding equipment needs to use gas as cutting raw material, the relevant pipe and gas path especially needs to attract the attention of the operator in the daily use process. Here, the Shandong CNC welding equipment manufacturer lists some common pipe and gas path faults and solutions for you, hoping you can learn from them.

要说明的是,管气路故障是指除了因为切割燃气气压、流速以及纯度等参数的关注外的气管气路故障,如果因气管气路堵塞或泄露造成事故,其危害往往是相当巨大的,轻则影响到切割质量,重则造成燃烧或者炸。

It should be noted that the failure of the gas pipeline refers to the failure of the gas pipeline in addition to the concern of the cutting gas pressure, flow rate, purity and other parameters. If the accident is caused by the blockage or leakage of the gas pipeline, the harm is often quite huge, ranging from affecting the cutting quality to burning or explosion.

1、减压阀的故障维修

1. Troubleshooting of pressure reducing valve

对减压阀的故障维修应调节减压器,将压力表调到需用的压力,调节过程中应使压力由小到大,确保减压器能连续调节。如不能连续调节或气体从阀中泄漏就须更换新的减压器。自行折装气体减压器之零部件,将会造成设备损坏,甚严重人身伤害。

For the failure maintenance of the pressure reducing valve, the pressure reducer should be adjusted first, and the pressure gauge should be adjusted to the required pressure. During the adjustment process, the pressure should be adjusted from small to large to ensure that the pressure reducer can be continuously adjusted. If it cannot be adjusted continuously or the gas leaks from the safety valve, a new pressure reducer must be replaced. Self-folding the components of the gas pressure reducer will cause equipment damage and even serious personal injury.

2、气路系统故障维修常见气路维护主要有两方面,除可经常检查气路系统,发现漏气及不能正常使用的零部件应及时处理,保证气路畅通外;还应经常擦拭气路的灰尘及杂物,防止气路过早老化。

2. There are two main aspects of common gas path maintenance for gas path system fault repair. In addition to regular inspection of the gas path system, the gas leak and parts that cannot be used normally should be handled in time to ensure the smooth gas path; The dust and sundries in the gas circuit should also be cleaned regularly to prevent premature aging of the gas circuit.

3、割炬割嘴故障及维护

3. Failure and maintenance of cutting torch and nozzle

在配件选购上,我们建议用户使用厂家提供的原厂机用,在长期的使用过程中,割炬密封面损坏,与割嘴密封不严,须用专门工具修复。另外割炬也采用专门厂家生产的标准快速割嘴,对于新割嘴,须经检查合格方可使用。割嘴污染了需用专门工具清理预热火焰孔及切割氧通道。

In the purchase of accessories, we recommend that users use the original machine provided by the manufacturer. In the long-term use process, the sealing surface of the cutting torch is damaged, and the sealing with the cutting nozzle is not tight, so special tools must be used to repair. In addition, the cutting torch also adopts the standard quick cutting nozzle produced by a special manufacturer. For new cutting nozzle, it can only be used after passing the inspection. The cutting nozzle is polluted. It is necessary to use special tools to clean the preheating flame hole and cut the oxygen channel.

4、回火防止器的维修

4. Maintenance of flashback preventer

回火防止器是保证的重要部件,根据部门的要求,回火防止器严禁私自拆卸。因此,回火防止器使用久后气阻,保证不了气体流量要求时或漏气,一定请专门的人员更换。

The flashback preventer is an important part to ensure safety. According to the requirements of the safety department, it is forbidden to disassemble the flashback preventer without permission. Therefore, if the flashback preventer is used for a long time and the gas resistance cannot meet the gas flow requirements or leaks, it must be replaced by a special person.

数控焊接设备气路常见故障如何处理?我们从以上四个方面来讲解了这个问题,当然平常使用中要注意设备的维护,避免大量问题的突然出现。更多事项就来我们网站http://www.tayfsk.com进行咨询!

How to deal with the common faults of the gas circuit of the numerical control welding equipment? We have explained this problem from the above four aspects. Of course, we should pay attention to the maintenance of the equipment in normal use to avoid the sudden emergence of a large number of problems. Come to our website for more matters http://www.tayfsk.com Consult!

上一篇:焊接变位机其夹具的选择

下一篇:焊接专机的运行离不开这些要点