具体讲解焊接专机分两类

来源:http://www.tayfsk.com/ 发布时间:2022-08-16 浏览次数:0

焊接专机是为特定的工件和一定形状的焊接接头而专门设计的焊接自动化设备,那么它能够分几类呢?下面山东焊接专机厂家为您讲解讲解。

Special welding machine is a welding automation equipment specially designed for specific workpieces and certain shapes of welding joints. How many types can it be divided into? Next, Shandong welding machine manufacturer will explain for you.

自适应控制自动化焊接专机

Adaptive control automatic welding machine

该类专机是一种自动化程度较高的焊接设备。它配备传感器和电子检测线路,对焊缝的轨迹自动导向和跟踪,有的设备还可以对焊接参数如焊接电流、焊接电压、焊接速度等实现闭环控制,整个焊接过程按预先设置的程序和工艺参数自动完成。

This kind of special machine is a kind of welding equipment with high degree of automation. It is equipped with sensors and electronic detection circuits to automatically guide and track the trajectory of the weld. Some equipment can also realize closed-loop control of welding parameters such as welding current, welding voltage and welding speed. The whole welding process is automatically completed according to the preset procedures and process parameters.

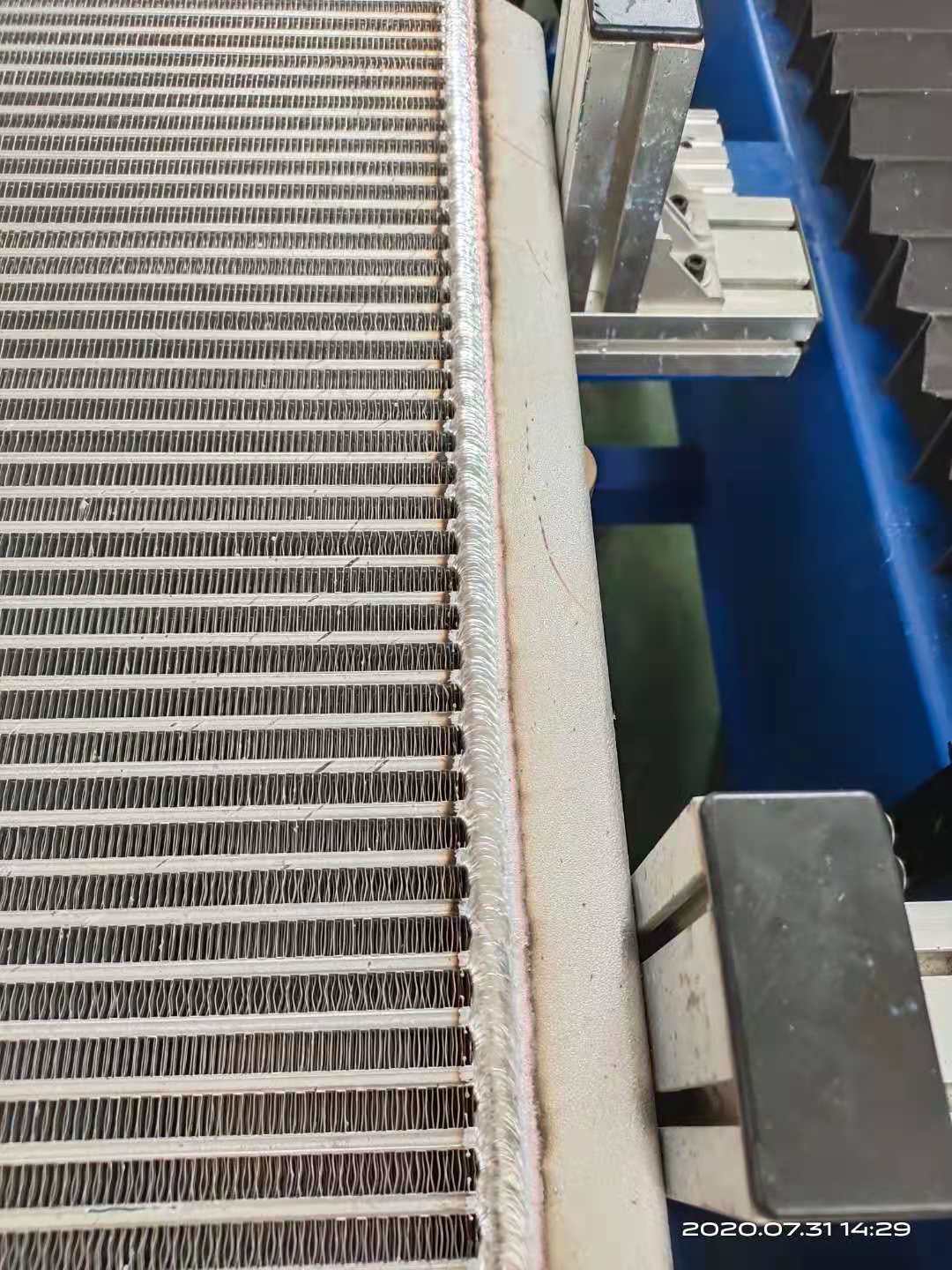

比如,大一点的筒体或管类零件,如右图所示,管道预置焊接专机 要保证工件的一致性和达到很高的配合精度是非常困难的,需要花费更大的成本。

For example, for larger cylinders or pipe parts, as shown in the right figure, it is very difficult to ensure the consistency of workpieces and high fitting accuracy of the pipe preset welding machine, which requires more costs.

该焊接专机采用了弧长跟踪器和焊枪摆动器。由于工件表面的凹凸不平,需要焊枪随着工件表面的高低不平,需要进行上下运动,以保持焊枪与工件表面的距离一致,从而保证电弧的稳定性。同时可以自动实现多层焊接。若焊接两层,当焊接完一周后,跟踪器检测到表面高度增加,则可以自动将焊枪提高。

The welding machine adopts arc length tracker and welding gun swinging device. Due to the uneven surface of the workpiece, the welding gun needs to move up and down along with the uneven surface of the workpiece to keep the distance between the welding gun and the workpiece surface consistent, so as to ensure the stability of the arc. At the same time, multi-layer welding can be realized automatically. If two layers are welded, the tracker can automatically raise the welding torch if it detects that the surface height increases after one week of welding.

智能化自动焊接设备

Intelligent automatic welding equipment

它利用各类传感元件,如视觉传感器、触角传感器、光敏传感器等,并借助计算机软件系统、数据库、系统而具有识别、判断、实时检测、运算、自动编程、焊接参数调用等,操作人员只需在人机界面上输入材料的牌号、板厚、坡口形式、焊丝牌号和直径、焊剂或保护气体种类等,焊接工艺参数自动生成或调用相应参数。

It uses various sensing elements, such as vision sensor, feeler sensor, photosensitive sensor, etc., and has the functions of identification, judgment, real-time detection, calculation, automatic programming, welding parameter call, etc. with the help of computer software system, database and expert system. The operator only needs to input the material grade, plate thickness, groove form, welding wire grade and diameter, flux or shielding gas type on the human-machine interface, Welding process parameters are automatically generated or called.

即可完成全自动焊接。由于这类设备成本非常高,实际影响焊接质量的因素很多,比如气体的纯度,流量,焊接电流,电压,电源输入的波动,工件的水汽或锈蚀、焊缝的宽窄,焊缝的高低等等,所以很难真正完成智能化焊接,在实际生产中很少用到。

The fully automatic welding can be completed. As the cost of such equipment is very high, there are many factors that actually affect the welding quality, such as the purity of gas, flow, welding current, voltage, fluctuation of power input, water vapor or corrosion of workpieces, width and width of welds, height of welds, etc., so it is difficult to truly complete intelligent welding, which is rarely used in actual production.

自动焊接专机是用于自动化生产的,要求人工或者机械手上下工件,焊接工装夹具自动将工件固定,定位,自动启动焊接电源的电弧,自动送丝和焊枪或工件的自动移动,焊接完成后自动退回,人工或机械手取下工件,其组成主要由焊接系统、机械系统、电气控制系统构成。

The automatic welding machine is used for automatic production. It requires manual or mechanical hands to move up and down the workpiece. The welding fixture automatically fixes and positions the workpiece, automatically starts the arc of the welding power supply, automatically feeds the wire and automatically moves the welding gun or workpiece, automatically returns after the welding is completed, and manually or mechanically removes the workpiece. Its composition is mainly composed of the welding system, mechanical system and electrical control system.

当然该设备使用前后期间的注意事项也不少,要多多去了解才行,这样才能在保障自己人身的前提下顺利完成施工,更多事项就来我们网站http://www.tayfsk.com咨询了解吧。

Of course, there are many precautions before and after the use of the equipment. We need to learn more about it so that the construction can be completed smoothly on the premise of ensuring our personal safety. For more information, please visit our website http://www.tayfsk.com Consult and understand.

上一篇:焊接加工的注意及控制焊接应力措施

下一篇:数控切割机的正确使用非常关键