焊接机器人对焊丝的质量要求是什么?

来源:http://www.tayfsk.com/ 发布时间:2021-10-19 浏览次数:0

要了解焊接机器人对焊丝的质量要求是什么,我们要知道这个黄色的东西实际上是焊丝和焊接母材中的杂质,主要是硅锰元素在焊接过程中高温氧化跟保护气体中的CO2发生化学反应,分解形成氧化硅、氧化锰形成的氧化物,有点像手工焊条焊接时的焊渣。尽管这些现象甚可以用焊接机器人制造,但这些氧化物除了外观上有一点瑕疵外,对焊接质量没有任何不良影响,用刷子也可以轻松地将其。

To understand the quality requirements of welding robot for welding wire, first of all, we should know that this yellow thing is actually the impurities in the welding wire and welding base metal, mainly the high-temperature oxidation of silicon and manganese in the welding process, which reacts with CO2 in the shielding gas and decomposes into oxides formed by silicon oxide and manganese oxide, which is a bit like the welding slag during manual electrode welding. Although these phenomena can even be made by welding robots, these oxides have no adverse impact on the welding quality except for a little defect in appearance, and can be easily removed by brush.

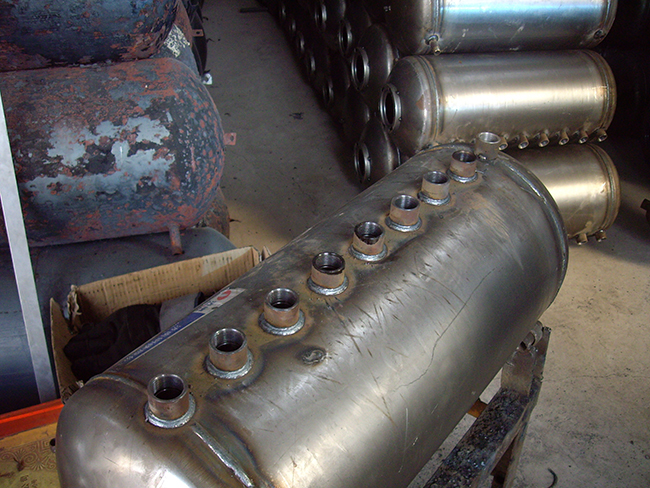

可根据需要选择圆筒或圆盘装焊丝。为降低更换焊丝的频率,机器人应选择桶装焊丝,但由于采用桶装焊丝,送丝软管长度大,阻力大,对焊丝挺度等质量要求较高。

Cylinder or disc welding wire can be selected as required. In order to reduce the frequency of welding wire replacement, the robot should choose barreled welding wire. However, due to the use of barreled welding wire, the length of wire feeding hose is large, the resistance is large, and the quality requirements such as welding wire stiffness are high.

它不仅具有高能率和稳定效率的优点,而且具有很好的灵活性,即使在再复杂的环境中,也能保证焊接机器人稳定、高能地运行。它与设备的构成密不可分,包括主体、焊接电源、一维重型滑台、机器人L臂、清枪剪、控制系统等。

It not only has the advantages of high energy rate and stable efficiency, but also has good flexibility. Even in the most complex environment, it can ensure the stable and high-energy operation of the welding robot. It is closely related to the composition of the equipment, including the main body, welding power supply, one-dimensional heavy slide, robot l-arm, gun cleaning shear, control system, etc.

焊母金属元素中有多少硅锰元素,这种现象是肯定会存在的,要减少这些氧化物,可选用含硅锰元素较少的焊丝,保护气体换成CO2含量少的混合气,焊接出的氧化物就会少一些,黄色的斑就会少很多。

The phenomenon of how many silicon and manganese elements are in the parent metal elements of welding will certainly exist. To reduce these oxides, the welding wire with less silicon and manganese elements can be selected, and the shielding gas can be replaced with the mixture with less CO2 content, so that there will be less oxides and yellow spots.

在镀铜质量稍差的焊丝时,焊丝表面的镀铜由于摩擦和脱落,会降低导管内容积,高速送丝时阻力增大,焊丝无法平滑送出,产生的抖动使电弧不稳,从而影响到焊接质量。严重者,发生卡死,使机器人停止运转,因此应及时清理焊丝管。

In case of welding wire with poor copper plating quality, the copper plating on the surface of the welding wire will reduce the volume in the conduit due to friction and falling off, increase the resistance during high-speed wire feeding, the welding wire cannot be sent out smoothly, and the resulting jitter will make the arc unstable, thus affecting the welding quality. In serious cases, the robot is stuck and stops running. Therefore, the welding wire pipe shall be cleaned in time.

上一篇:使用焊割设备过程中的注意事项!

下一篇:焊接机器人厂在技能包装的使用