焊 接专机器人有哪些特点呢?

来源:http://www.tayfsk.com/ 发布时间:2021-03-29 浏览次数:0

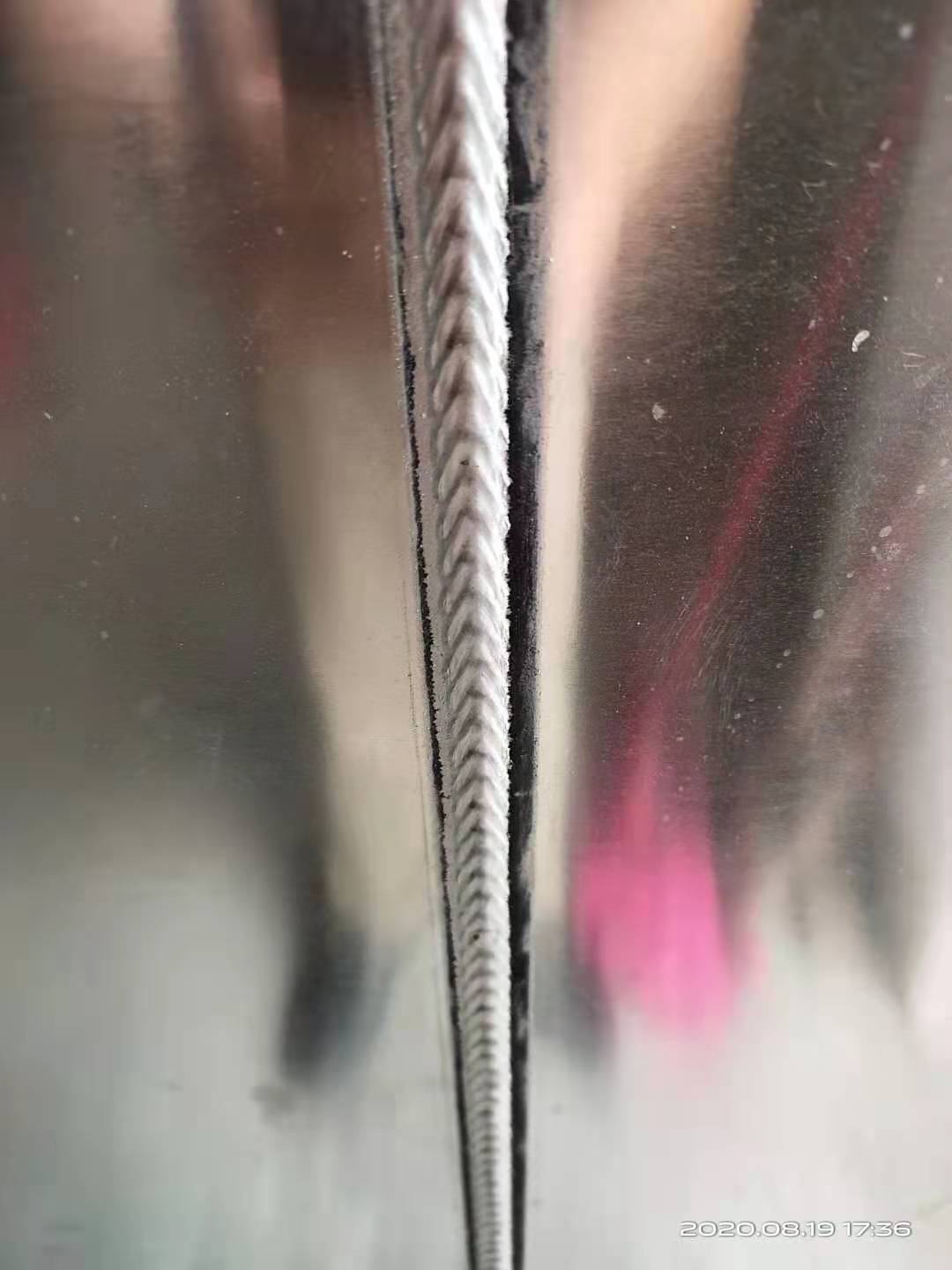

焊 接机器人有稳定和提高焊 接质量,保证其均一性。焊 接参数如焊 接电流、电压、焊 接速度和干伸长量等对焊 接结果有着决定作用。采用机器人焊 接时,每条焊 缝的焊 接参数都是恒定的,焊缝质量受人为因素影响较小,降低了对工人操作技术的要求,因此焊 接质量稳定。而人工焊 接时,焊 接速度、干伸长量等都是变化的,很难做到质量的均一性。焊 接机器人

The welding robot can stabilize and improve the welding quality to ensure its uniformity. Welding parameters such as welding current, welding voltage, welding speed and dry elongation have a decisive role in welding results. When using robot welding, the welding parameters of each welding seam are constant, and the welding quality is less affected by human factors, which reduces the requirements for workers' operation technology, so the welding quality is stable. However, in manual welding, the welding speed and dry elongation are variable, so it is difficult to achieve the uniformity of quality. Welding robot

对于点焊来说,工人无需搬运笨重的手工焊钳,使工人从高强度的体力劳动中解脱出来。提高劳动生产率。随着高速焊 接技术的应用,采用机器人焊 接,效率提高得更为明显。

For spot welding, workers do not need to carry heavy manual welding tongs, so that workers are free from high-intensity physical labor. Improve labor productivity. With the application of high-speed welding technology, the efficiency of robot welding is improved more obviously.

产品周期明确,容易控制产品产量。机器人的生产节拍是固定的,因此安排生产计划非常明确。缩短产品改型换代的周期,减小相应的设备投资。可实现小批量产品的焊 接自动化。机器人与专机的区别就是可以通过修改程序以适应不同工件的生产。 环缝焊 接专机

Clear product cycle, easy to control product output. The production rhythm of the robot is fixed, so the production plan is very clear. Shorten the cycle of product upgrading and reduce the corresponding equipment investment. It can realize the welding automation of small batch products. The difference between robot and special machine is that it can adapt to the production of different workpieces by modifying the program. Special machine for girth welding

焊 接机器人具有焊 接质量稳定、改善工人劳动条件、提高劳动生产率等特点,广泛应用于汽车、工程机械、通用机械、金属结构和兵器工业等行业。这对于我国的经济发展速度以及经济总量来说显然是不匹配的,这说明我国制造业的自动化程度有待进一步提高,另一方面也反映了我国劳动力成本的低廉,制造业自动化水平以及工业机器人应用程度的提高受到限制。

Welding robot is widely used in automobile, engineering machinery, general machinery, metal structure and weapon industry because of its stable welding quality, improved working conditions and productivity. This obviously does not match the speed of China's economic development and the total economic volume, which shows that the degree of automation of China's manufacturing industry needs to be further improved. On the other hand, it also reflects the low labor cost of China, and the improvement of the level of automation of manufacturing industry and the application degree of industrial robots is limited.

当前焊 接机器人的应用迎来了难得的发展机遇。一方面,随着技术的发展,焊 接机器人的不断下降,性能不断提升;另一方面,劳动力成本不断上升,我国由制造大国向制造强国迈进,需要提升加工手段,提高产品质量和增强企业竞争力,这一切预示着机器人应用及发展前景空间巨大。

At present, the application of welding robot ushers in a rare development opportunity. On the one hand, with the development of technology, the price of welding robot continues to decline, and the performance continues to improve; on the other hand, the labor cost continues to rise. As China moves forward from a big manufacturing country to a powerful manufacturing country, it needs to improve the processing means, improve the product quality and enhance the competitiveness of enterprises. All these indicate that there is a huge space for robot application and development.

上一篇:自动焊接设备一般由哪几个部分组成的?

下一篇:自动焊接设备未来的使用效果不可限量!