自动焊接设备的突出之处

来源:http://www.tayfsk.com/ 发布时间:2024-01-22 浏览次数:0

自动焊接设备是指在制造和加工过程中,能够自动完成焊接任务的机器和设备。这些设备通常采用的焊接技术,如激光焊接、电子束焊接、摩擦焊接等,具有有效、高精度和可靠性的特点。自动焊接设备在提高焊接效率、保证焊接质量、降低生产成本等方面具有显著优势,下文将展开介绍自动焊接设备的特点,以帮助读者更好地了解和应用这一技术。

Automatic welding equipment refers to machines and equipment that can automatically complete welding tasks during manufacturing and processing. These devices typically use advanced welding techniques such as laser welding, electron beam welding, friction welding, etc., which are effective, high-precision, and reliable. Automatic welding equipment has significant advantages in improving welding efficiency, ensuring welding quality, and reducing production costs. The following will introduce the characteristics of automatic welding equipment to help readers better understand and apply this technology.

自动焊接设备的特点有哪些?

What are the characteristics of automatic welding equipment?

1.有效稳定的生产能力

1. Effective and stable production capacity

自动焊接设备具备有效稳定的生产能力,可大幅提高焊接效率。在传统的焊接过程中,工人的技能水平、疲劳程度等因素都会影响到焊接质量与效率。而自动焊接设备则可以连续进行焊接工作,不受人为因素的影响,且设备采用高精度的控制系统,保证了焊接的稳定性和一致性。

Automatic welding equipment has effective and stable production capacity, which can significantly improve welding efficiency. In traditional welding processes, factors such as the skill level and fatigue level of workers can affect welding quality and efficiency. Automatic welding equipment can continuously perform welding work without being affected by human factors, and the equipment adopts a high-precision control system to ensure the stability and consistency of welding.

2.高精度的焊接控制

2. High precision welding control

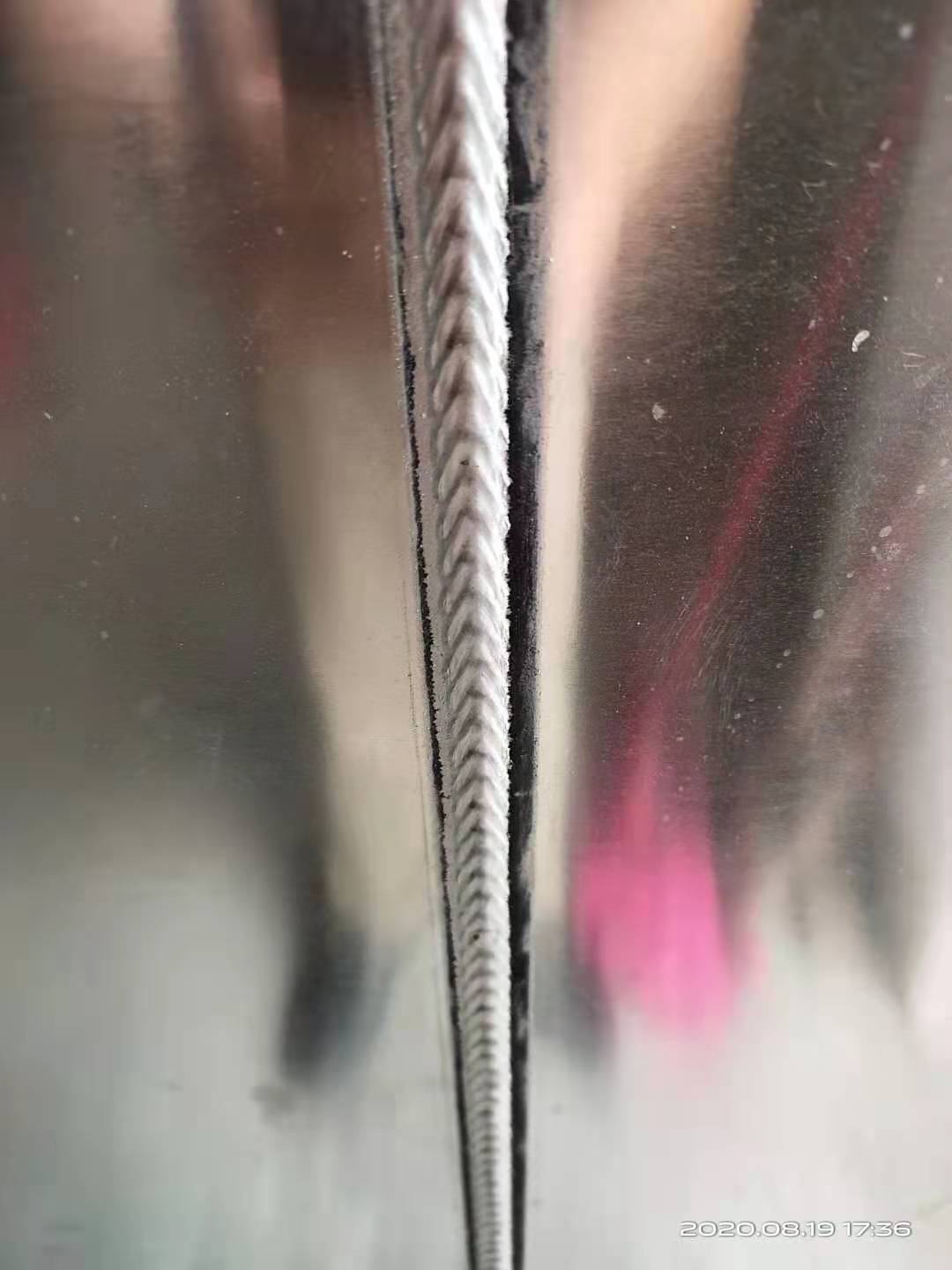

自动焊接设备采用的控制系统和高精度的运动系统,可以实现高精度的焊接控制。设备采用高精度的传感器和检测元件,对焊接过程中的各项参数进行实时监测和调整,保证了焊接过程中的稳定性和准确性。此外,自动焊接设备还可以通过软件系统进行准确的轨迹规划和运动控制,实现复杂焊缝的准确焊接。

The automatic welding equipment adopts advanced control systems and high-precision motion systems, which can achieve high-precision welding control. The equipment adopts high-precision sensors and detection components to monitor and adjust various parameters during the welding process in real time, ensuring stability and accuracy during the welding process. In addition, automatic welding equipment can also achieve accurate trajectory planning and motion control through software systems, achieving accurate welding of complex welds.

自动焊接设备的特点

The characteristics of automatic welding equipment

3.广泛的适用性

3. Wide applicability

自动焊接设备适用于各种材料和焊接工艺的要求。不同的材料和焊接工艺对焊接设备的性能要求不同,而自动焊接设备在设计时充分考虑了各种因素,可以适应不同的焊接要求。例如,针对不锈钢、碳钢、铝合金等不同材料的焊接,自动焊接设备可以采用相应的焊接工艺和参数设置,实现高质量的焊接效果。

Automatic welding equipment is suitable for the requirements of various materials and welding processes. Different materials and welding processes have different performance requirements for welding equipment, and automatic welding equipment is designed with full consideration of various factors, which can adapt to different welding requirements. For example, for welding different materials such as stainless steel, carbon steel, and aluminum alloy, automatic welding equipment can adopt corresponding welding processes and parameter settings to achieve high-quality welding results.

4.易于操作和维护

4. Easy to operate and maintain

自动焊接设备的操作和维护相对简单,降低了对操作人员的技能要求。自动焊接设备通常采用人机交互界面,操作人员可以通过简单的操作实现设备的控制和调整。此外,设备的模块化设计也使得维护更加方便快捷,降低了设备的维护成本。

The operation and maintenance of automatic welding equipment are relatively simple, reducing the skill requirements for operators. Automatic welding equipment usually adopts a human-machine interaction interface, and operators can control and adjust the equipment through simple operations. In addition, the modular design of the equipment also makes maintenance more convenient and efficient, reducing the maintenance cost of the equipment.

5.可持续性和

5. Sustainability and environmental protection

自动焊接设备在生产过程中具有可持续性和的优势。自动焊接设备可以大幅减少人工焊接时产生的烟尘、弧光等污染物对环境的污染。其次,通过准确的控制系统和优化的工艺参数,自动焊接设备可以减少能源的浪费,实现减排。此外,自动焊接设备的使用还可以降低人工成本,为企业创造更大的经济效益。

Automatic welding equipment has the advantages of sustainability and environmental protection in the production process. Automatic welding equipment can significantly reduce the environmental pollution caused by pollutants such as smoke and arc light generated during manual welding. Secondly, through accurate control systems and optimized process parameters, automatic welding equipment can reduce energy waste and achieve energy conservation and emission reduction. In addition, the use of automatic welding equipment can also reduce labor costs and create greater economic benefits for enterprises.

以上就是对自动焊接设备特点的介绍,通过集成传感器、机器视觉、人工智能等技术,自动焊接设备将具备更强的环境感知和适应能力,进一步提高焊接质量和效率。在未来的工业生产中发挥重要作用,从而提高生产效率和质量,降低成本和风险,推动工业生产的持续发展。

The above is an introduction to the characteristics of automatic welding equipment. By integrating technologies such as sensors, machine vision, and artificial intelligence, automatic welding equipment will have stronger environmental perception and adaptability, further improving welding quality and efficiency. Play an important role in future industrial production, thereby improving production efficiency and quality, reducing costs and risks, and promoting the sustainable development of industrial production.

本文由山东数控焊接设备提供技术支持,更多的详细精彩内容请点击我们的网站http://www.tayfsk.com,我们将会全心全意为您提供满意的服务。

This article is supported by Shandong CNC welding equipment. For more detailed and exciting content, please click on our website http://www.tayfsk.com We will wholeheartedly provide you with satisfactory service.

上一篇:激光焊接设备如何能完成焊接效果?

下一篇:自动焊接设备应用标准规范有哪些?