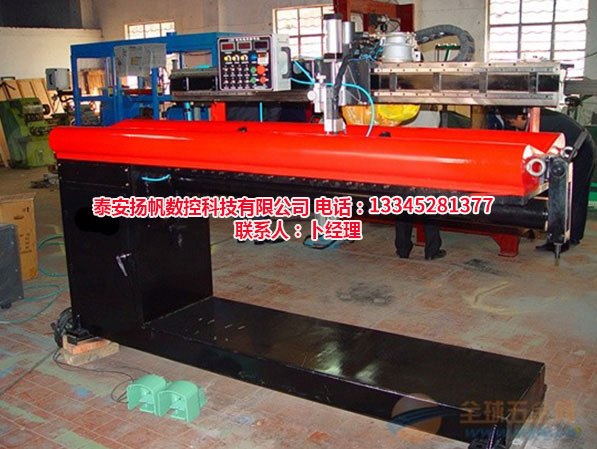

自动焊专机的功用特性介绍!

来源:http://www.tayfsk.com/ 发布时间:2021-09-17 浏览次数:0

自动焊的功用特性:顺应管管、管弯头、管三通、管高颈法兰对接;管法兰、弯头法兰角接。顺应碳钢、低合金钢、不锈钢等多种材质的焊接可搭载氩弧焊、二保焊、MIG/MAG焊、等离子焊等多种焊接设备。

Functional characteristics of automatic welding: conform to the butt joint of pipe, pipe elbow, pipe tee and pipe high neck flange; Pipe flange, elbow flange angle joint. Comply with the welding of carbon steel, low alloy steel, stainless steel and other materials, and can be equipped with argon arc welding, secondary protection welding, MIG / MAG welding, plasma welding and other welding equipment.

自动焊机的特点:

Features of automatic welding machine:

1、采用直流伺服电机,性能稳定,使用寿命长。

1. DC servo motor is adopted, with stable performance and long service life.

2、采用10寸触摸屏做为人机交互界面,一看即懂的焊接工艺控制过程,形象直观,简单、易操作。

2. The 10 Inch Touch screen is used as the man-machine interface to understand the welding process control process at a glance, which is intuitive, simple and easy to operate.

3、电弧自动跟踪功能,也可关闭弧长控制功能,手动调节弧长。

3. The automatic arc tracking function can also turn off the arc length control function and manually adjust the arc length.

4、精密的无限回转式旋转结构,送丝、水、电、气无缠绕;自带一体式送丝机,使送丝方便可靠。

4. Precise infinite rotary structure, no winding of wire feeding, water, electricity and gas; The self-contained integrated wire feeder makes wire feeding convenient and reliable.

5、该设备可存储60套焊接工艺参数;一个焊接工艺程序可分16个区间,以满足工件不同时段的焊接要求。

5. The equipment can store 60 sets of welding process parameters; A welding procedure can be divided into 16 sections to meet the welding requirements of workpiece in different periods.

近二十年来,随着数字化、自动化、计算机技术、机械设计技术的发展,以及人们对产品的质量要求的提高,焊接质量、美观度等得到了更大的重视。特别是在08年金融危机以后,随着我国劳动成本的增加,以及对工人的身体健康的重视和对提高生产效率的要求,。

In the past two decades, with the development of digitization, automation, computer technology and mechanical design technology, as well as the improvement of people's requirements for product quality, welding quality and aesthetics have been paid more attention. Especially after the 2008 financial crisis, with the increase of China's labor cost, the attention to the health of workers and the requirements to improve production efficiency,.

在现代工业生产中,越来越多的焊接生产过程中开始采用自动焊接专机。可以通过电气控制,气动控制和液压控制技术,实现对电动机、气动执行元件、液压执行元件的旋转或移动,实现工件焊缝与焊枪的相对运动,从而自动完成焊接接头的焊接工作。

In modern industrial production, more and more automatic welding machines are used in welding production. Through electrical control, pneumatic control and hydraulic control technology, the rotation or movement of motor, pneumatic actuator and hydraulic actuator can be realized, and the relative movement of workpiece weld and welding gun can be realized, so as to automatically complete the welding of welded joints.

上一篇:焊接变形和应力产生的原因和预防

下一篇:自动焊专机的功用特性介绍!