数控切割机传动滑轴故障排除及维护!

来源:http://www.tayfsk.com/ 发布时间:2021-09-03 浏览次数:0

数控自动化机床的应用分支中的数控切割机能满足国内大量生产型企业的下料加工,在机床工作原理方面,数控切割机仍然沿用市面上主要的三轴传动设计,通过平面坐标定位以达到精切割下料的目的。

The NC cutting function in the application branch of NC automatic machine tool meets the blanking processing of a large number of domestic production-oriented enterprises. In terms of the working principle of the machine tool, the NC cutting machine still follows the main three-axis transmission design in the market, and achieves the purpose of fine cutting and blanking through plane coordinate positioning.

数控切割机的机械部分维护工作中,主轴与滑动轴作为传动部分主要组成部分,其维护处理相对较多。两轴的损耗及故障多集中在日常维护工作不到位导致,另外对于数控切割机的使用环境这里也需要有一定的要求,对于厂房内金属粉尘或残渣较多也可能导致部件损伤。这里就一些简单的故障处理方法整理说明如下:

In the maintenance of the mechanical part of NC cutting machine, the main shaft and sliding shaft are the main components of the transmission part, and there are relatively many maintenance treatments. The loss and faults of the two shafts are mostly caused by the inadequate daily maintenance. In addition, there are certain requirements for the use environment of the NC cutting machine. More metal dust or residues in the plant may also lead to component damage. Here are some simple troubleshooting methods:

1、滑动轴承表面被研伤后,维护方案应是刮石匠方法维护。一般来说,滑动轴承都留有可供调整和修理的余量,可以满足数控切割机的一个修理周期。如果研伤十分严重,修理余量不能满足,就需要考虑更换了。两半瓦式滑动轴承研伤后,可以减薄垫片重新组装后,刮研轴瓦内孔要求精度,维护后继续使用。

1. After the sliding bearing surface is abraded, the maintenance scheme shall be maintained by the stone scraper method. Generally speaking, the sliding bearing has a margin for adjustment and repair, which can meet a repair cycle of NC cutting machine. If the grinding damage is very serious and the repair allowance cannot be met, replacement needs to be considered. After the two half pad sliding bearing is abraded, it can be thinned. After reassembly, scrape and grind the inner hole of the bearing bush to the required accuracy, and continue to use after maintenance.

2、当轴颈有研伤后,可采用磨小轴颈、更换滑动轴承的方法。但轴颈修磨不宜太大,比如机床主轴,修磨量不宜超过轴颈表面淬火,或者渗碳、氮化、氰化的厚度、修磨后轴颈表面硬度不得低于原设计硬度的下限;对于传动轴来说,轴颈不应小于装配时在装配方向前端轴颈或凸台的尺寸。

2. When the journal is abraded, the method of grinding the journal and replacing the sliding bearing can be used. However, the journal grinding should not be too large. For example, for the machine tool spindle, the grinding amount should not exceed the journal surface quenching, or the thickness of carburizing, nitriding and cyanidation, and the surface hardness of the journal after grinding shall not be lower than the lower limit of the original design hardness; For the drive shaft, the journal shall not be less than the size of the front journal or boss in the assembly direction at the time of assembly.

如果用焊补的方法来维护数控切割机轴颈,那么要考虑焊补加热过程对轴的几何精度、机械强度及表面硬度的影响。轴颈维护后,一般都需要按轴颈重新配做滑动轴承(或称轴套)。

If the welding repair method is used to maintain the Journal of NC cutting machine, the influence of welding repair heating process on the geometric accuracy, mechanical strength and surface hardness of the shaft should be considered. After journal maintenance, sliding bearings (or shaft sleeves) generally need to be reconfigured according to journal.

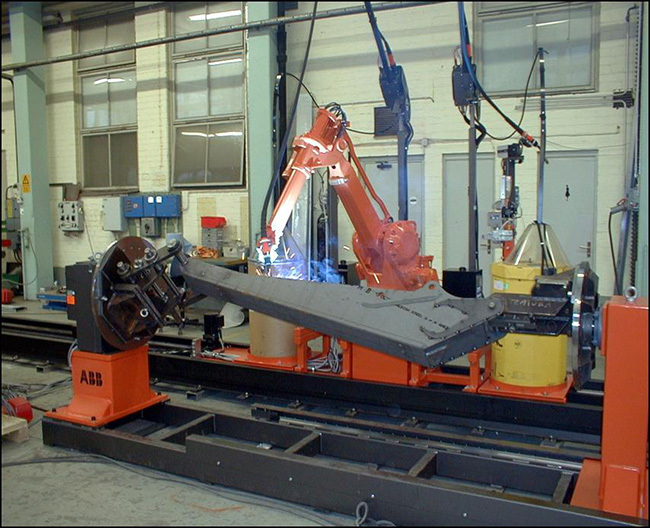

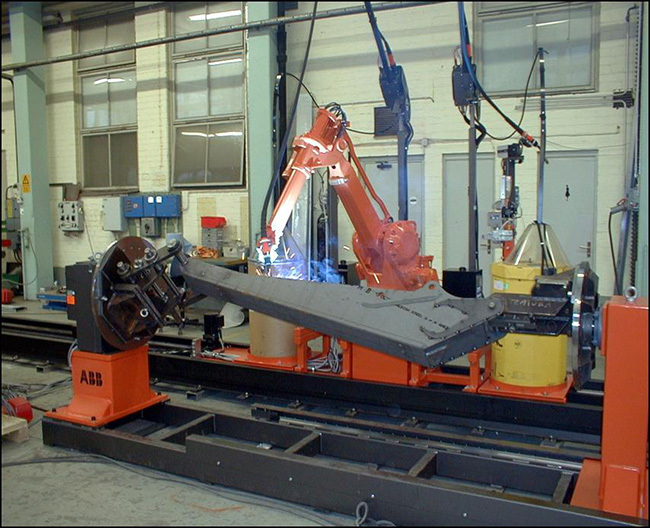

上一篇:自动焊接机器人实施的功能要求是什么?

下一篇:焊接滚轮架上用的轴承窜动的原因