环缝焊接专机的工作原理及特点介绍

来源:http://www.tayfsk.com/ 发布时间:2023-12-14 浏览次数:0

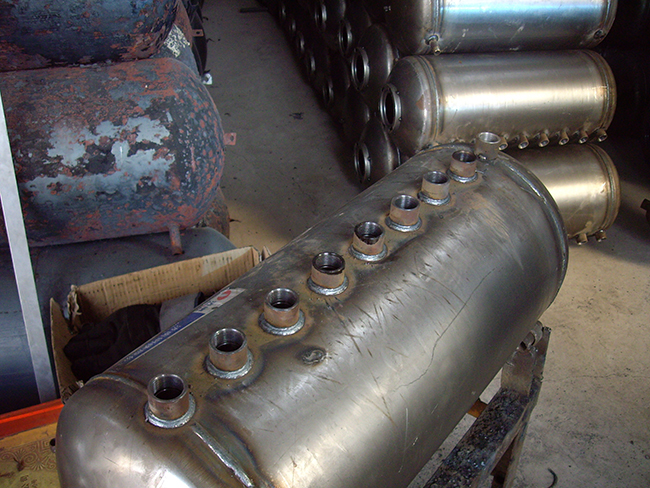

环缝焊接专机是一种用于自动化环缝焊接的设备。它通常由焊枪、焊接电源、控制系统和机械部分组成。

The circumferential welding machine is a device used for automated circumferential welding. It usually consists of a welding gun, welding power supply, control system, and mechanical parts.

环缝焊接专机的工作原理基于焊接过程的几个关键要素:电弧、电流、焊接材料和焊接接头。焊接过程中,两个被焊接的金属工件之间产生一定的电阻,从而产生高温,使他们在高温下熔化并连接在一起。

The working principle of the circumferential welding machine is based on several key elements of the welding process: arc, current, welding material, and welding joint. During the welding process, a certain resistance is generated between two metal workpieces being welded, resulting in high temperatures that melt and connect them together.

在工作时,环缝焊接专机的焊枪先通过控制系统移动到焊接位置。焊枪上有一个电极,通过电极与金属工件建立一定的电弧电流。同时,焊接电源会提供所需的电能,并根据预设的焊接参数来调整电弧电流的大小和稳定性。

During work, the welding gun of the circumferential welding machine is first moved to the welding position through the control system. There is an electrode on the welding gun, which establishes a certain arc current with the metal workpiece through the electrode. At the same time, the welding power supply will provide the required electrical energy and adjust the arc current and stability based on preset welding parameters.

焊接电源通常是一台变压器或逆变器装置,通过控制电极间的电压和电流来实现控制焊接过程中产生的电弧。变压器将主电源的电压降低到焊接需要的低电压,逆变器则将主电源的交流电转换成直流电。这样,焊接电源能够根据焊接参数的变化实时调整焊接电弧的能量。

Welding power supply is usually a transformer or inverter device that controls the voltage and current between the electrodes to control the arc generated during the welding process. The transformer reduces the voltage of the main power supply to the low voltage required for welding, while the inverter converts the AC power of the main power supply into DC power. In this way, the welding power supply can adjust the energy of the welding arc in real-time based on changes in welding parameters.

焊接材料通常是金属焊丝,它根据焊接需要的材料和性质进行选择。焊丝一般是高温下能够熔化并与金属工件产生良好的结合的材料。焊丝通过焊接枪的喂丝机构将其送入焊接接头的位置。

Welding materials are usually metal welding wires, which are selected based on the materials and properties required for welding. Welding wire is generally a material that can melt at high temperatures and form a good bond with metal workpieces. The welding wire is fed into the position of the welding joint through the wire feeding mechanism of the welding gun.

控制系统是环缝焊接专机的核心部分,它通过实时监测焊接参数和相关传感器的反馈信息,来精确控制焊接过程。控制系统根据预设的焊接参数,包括焊接电流、电压、喂丝速度等参数,来调节焊接电弧的能量和稳定性。同时,控制系统还会对焊接过程进行监控,确保焊接接头的质量和稳定性。

The control system is the core part of the circumferential welding machine, which precisely controls the welding process by monitoring welding parameters in real-time and feedback information from relevant sensors. The control system adjusts the energy and stability of the welding arc based on preset welding parameters, including welding current, voltage, wire feeding speed, and other parameters. At the same time, the control system will also monitor the welding process to ensure the quality and stability of the welded joints.

机械部分是环缝焊接专机的实体部分,它包括焊接枪的运动机构、喂丝机构和工作台等。焊接枪的运动机构通常由伺服电机、齿轮传动系统和导轨组成,通过控制系统的指令来实现焊接枪在焊接接头上的移动。喂丝机构通过驱动机构将焊丝送入焊接接头的位置。工作台则用于支撑和固定焊接工件,确保焊接过程的稳定性和准确性。

The mechanical part is the physical part of the circumferential welding machine, which includes the motion mechanism of the welding gun, the wire feeding mechanism, and the workbench. The motion mechanism of a welding gun is usually composed of a servo motor, a gear transmission system, and a guide rail. The movement of the welding gun on the welding joint is achieved through the instructions of the control system. The wire feeding mechanism sends the welding wire into the position of the welding joint through the driving mechanism. The workbench is used to support and fix the welded workpiece, ensuring the stability and accuracy of the welding process.

总的来说,环缝焊接专机的工作原理是通过焊枪的移动、焊接电源的控制和焊接材料的喂丝,来实现对环缝焊接过程中电弧能量和稳定性的控制。控制系统和机械部分的配合则确保焊接过程的准确性和稳定性。这种自动化的焊接方式可以提高焊接效率、降低人工成本,并且能够实现高质量的焊接接头。

Overall, the working principle of the circumferential welding machine is to control the arc energy and stability during the circumferential welding process through the movement of the welding gun, control of the welding power supply, and feeding of welding materials. The coordination between the control system and the mechanical part ensures the accuracy and stability of the welding process. This automated welding method can improve welding efficiency, reduce labor costs, and achieve high-quality welding joints.

上一篇:自动追频超声波焊接机的工作原理

下一篇:式焊接专机与传统焊接设备有什么区别?