自动焊接专机焊接的特点有哪些?

来源:http://www.tayfsk.com/ 发布时间:2022-02-12 浏览次数:0

随着油气管道向大直径,长距离,高强度,高压发展,焊接难度越来越高,对焊接质量的要求也越来越高。手工电弧焊和药芯焊丝半自动焊接难以满足管道焊接的要求。全自动焊机可以轻松完成此过程。在管道工程建设中,焊接质量是保证工程质量非常重要的环节之一,焊接效率也直接影响施工进度,也就是说,焊接质量和焊接进度在很大程度上决定着质量和进度该项目。

With the development of oil and gas pipelines to large diameter, long distance, high strength and high pressure, the welding difficulty is higher and higher, and the requirements for welding quality are higher and higher. Manual arc welding and flux cored wire semi-automatic welding are difficult to meet the requirements of pipeline welding. Fully automatic welding machine can easily complete this process. In the construction of pipeline engineering, the welding quality is one of the very important links to ensure the engineering quality, and the welding efficiency also directly affects the construction progress, that is to say, the welding quality and welding progress determine the quality and progress of the project to a great extent.

全自动焊机设备,管道是固定的,焊车围绕管道旋转,以实现管道在所有位置(平面,垂直和向上)的焊接。焊接过程由机械和微型计算机完成,不受人类的影响。因此,管道全位置自动焊接机具有焊缝质量好,焊接效率高的优点。

Full automatic welding machine equipment, the pipeline is fixed, and the welding car rotates around the pipeline to realize the welding of the pipeline in all positions (plane, vertical and upward). The welding process is completed by machinery and microcomputer and is not affected by human beings. Therefore, the pipeline all position automatic welding machine has the advantages of good weld quality and high welding efficiency.

全自动焊机设备的工艺特点:

Process characteristics of fully automatic welding machine:

1.适用的管径越大,壁厚越厚,可以较好地反映焊接工艺。

1. The larger the applicable pipe diameter, the thicker the wall thickness, which can better reflect the welding process.

2,焊接工艺参数输入装置,可存储多套焊接工艺参数,可灵活选择多台焊机和不同规格的钢管;

2. The welding process parameter input device can store multiple sets of welding process parameters and flexibly select multiple welders and steel pipes of different specifications;

3.管道全自动焊机的大部分焊接工艺参数是通过焊接工艺参数输入来输入的,焊工无法对其进行修改以确保焊接工艺参数的准确性;4,焊接效率高,与手工电弧焊相比可提高2-5倍;

3. Most of the welding process parameters of the pipeline automatic welding machine are input through the welding process parameter input, and the welder cannot modify them to ensure the accuracy of the welding process parameters; 4. High welding efficiency, which can be increased by 2-5 times compared with manual arc welding;

5.焊接电弧燃烧比较稳定;

5. Welding arc combustion is relatively stable;

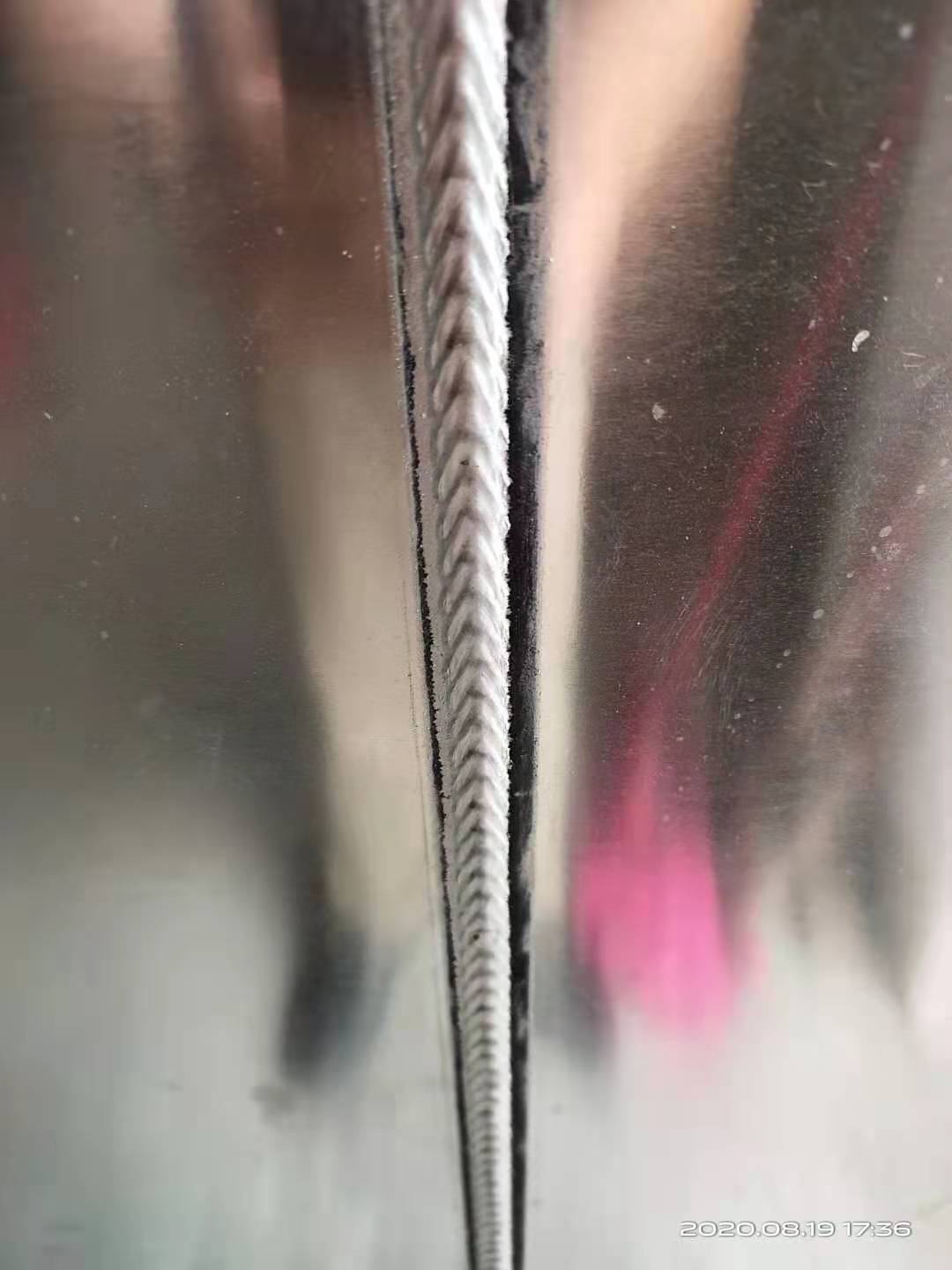

6.焊缝平整美观,内部质量好。

6. The weld is flat and beautiful, and the internal quality is good.

本文由山东焊接专机为您提供,我们的网站是http://www.tayfsk.com我们将以全心全意的热情为您提供服务,欢迎您的访问

This article is provided by Shandong welding machine. Our website is http://www.tayfsk.com We will wholeheartedly welcome your visit